Ang Spherical End Mill - Isang Tool para sa Paggupit at Paghubog

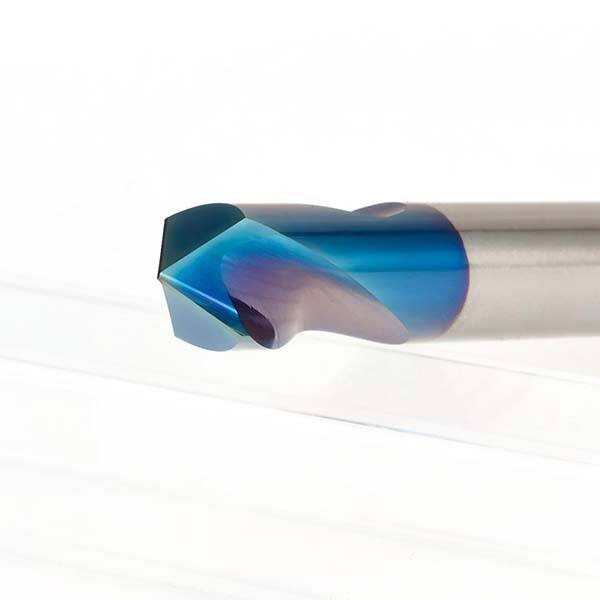

Pagod ka na ba sa paggamit ng mga tool na hindi gumagana? Ang mga spherical end mill ay ang perpektong tool para sa anumang paggupit o paghubog ng trabaho, katulad ng produkto ng Oucheng tulad ng solid carbide milling tool. Ang paggamit ng kanilang disenyo ay makabagong nag-aalok ng maraming benepisyo kaysa sa iba pang mga tool sa paggupit. Ipaalam sa amin tuklasin ang ilang mga benepisyo, kung paano gumagana ang mga ito, at kung paano sila magagamit mo.

Mayroong ilang mga pakinabang sa paggamit ng Spherical End Mill, kabilang ang:

1. Tumaas na pagiging epektibo: Kung ikukumpara sa dulo ay tradisyonal, pinapataas ng spherical end mill ang bilis ng pagputol ng hanggang 20%. Nangangahulugan ito na makukumpleto mo ang iyong mga trabaho nang mas mabilis at sapat na dahilan para sa mas higit na katumpakan, katulad ng kay Oucheng carbide endmill.

2. Superior Surface Finish: Kasama ang kanilang kakaibang hugis, ang spherical end mill ay nag-iiwan ng mas magandang surface finish sa iyong sariling workpiece. Ang mga ito ay perpekto para sa paglikha ng mga contour at mga hugis na tapered.

3. Pinababang Pagsuot ng Tool: Ang pagputol ay hugis bola ng spherical end mill na namamahagi ng cutting load nang pantay-pantay, na nagbibigay-daan para sa mas mahabang buhay ng mga tool at nabawasan ang mga gastos sa pagpapanatili.

4. Cost-Effective: Binabawasan ng mga spherical end mill kung gaano karaming mga tool ang kakailanganin mo para sa isang trabaho dahil maaari silang magsagawa ng maraming function. Isinasalin ito sa pagtitipid sa gastos para sa iyong proyekto.

Ang mga spherical end mill ay isang solusyon sa makabagong pagputol at paghubog, pati na rin ang 1 4 end mill mula sa Oucheng. Ang kanilang hugis ay natatanging mga pahintulot upang lumikha ng mga kumplikadong istruktura nang madali. Bukod pa rito, tinitiyak ng kanilang disenyo ang kaligtasan ng gumagamit. Hindi tulad ng tradisyonal na end mill, hindi sila gumagawa ng mga chips na maaaring magdulot ng pinsala o pinsala.

Ang paggamit ng isang Spherical End Mill ay medyo simple. Sundin ang mga hakbang na ito:

1. Piliin ang dulo na tama para sa iyong trabaho.

2. Ikabit ang huling end mill sa iyong spindle.

3. Itakda ang path ng device para sa workpiece batay sa tinukoy na hugis.

4. Simulan ang makina at hayaan ang tool na gumawa ng ilang trabaho.

Gawin ang lahat ng pagsisikap na gamitin ang kaligtasan ay angkop, sundin ang lahat ng inirerekumendang pamamaraan, at palaging gamitin ang mga tool ayon sa ibig sabihin.

Ipinagmamalaki lang namin ang pagbibigay ng mataas na kalidad na Spherical End Mill na maaasahan at mahusay, tulad ng 1 16 endmill ni Oucheng. Ang aming pangkat ng serbisyo sa consumer ay magagamit upang tumulong na sagutin ang anumang naaangkop na mga tanong o alalahanin na maaaring mayroon ka. Nagbibigay din kami ng suporta at pagsasanay upang matulungan kang makakuha ng marami sa aming mga produkto.

Namuhunan ang aming team sa pagbibigay sa iyo ng mga de-kalidad na makina. Mayroon kaming anim na axes at limang axis na Oucheng sourced machine grinding mula sa Germany, Switzerland at Japan pati na rin ang 50 set ng cylindrical grinding/tooling/grinding passivation/coreless machine, atbp. upang magawa ang buong proseso ng pagproseso para sa mga item na may mataas na precision na mga detalye.

Ang pagkakaroon ng spherical end mill ay nangangahulugan na madaling magdesisyon sa mga kumpanyang inuuna ang kasiyahan ng kliyente.

Ang aming Oucheng ay isang patuloy na ekspertong kumpanya na nakatuon sa pagbuo ng pagmamanupaktura, produksyon, at pamamahagi ng mga tool sa paggupit na ginawa mula sa matigas na haluang metal. Ang aming koponan ay binubuo ng mga propesyonal na kompanya ng seguro na may malawak na hanay ng. Ang aming mga pangunahing produkto ay cutting, switching, at drilling gear. Bilang karagdagan, nag-aalok kami sa mga customer ng mga customized na serbisyo para sa isang tunay na bilang ng hindi karaniwang alloy na hard equipment.

Nilagyan at na-import na pagsukat/domestic at isang kwalipikadong Koponan upang ipatupad ang spherical end mill, Ginabayan dahil sa patuloy na Pilosopiya ng negosyo ng "Zero Defects" at "Zero point" at dinisenyo na may mataas na katumpakan na Inspection Equipment na na-import upang matugunan ang Mga Pangangailangan ng Customer Sa pinakamataas na kalidad At Assurance ng halaga.