The Benefits and Uses associated with 1/4 End Mill

Are you searching for an instrument to improve your woodworking jobs? The 1/4 End Mill can help. This Oucheng milling end mill cutter, tool happens to be innovated to offer a safer and efficient experience and it’s woodworking., we shall discuss the advantages, innovation, safety, use, how to use, service, quality, and application of the 1/4 End Mill.

The Oucheng carbide end milling, 1/4 End Mill presents a number of advantages that surpass the router and its regular drill bits. Firstly, it produces smoother cuts on wood thanks to its design, makes it possible for the finer amount of accuracy. Moreover, it works at higher rates, which decreases the amount of time required for the woodworking task. This particular feature, in change, increases productivity and it’s overall.

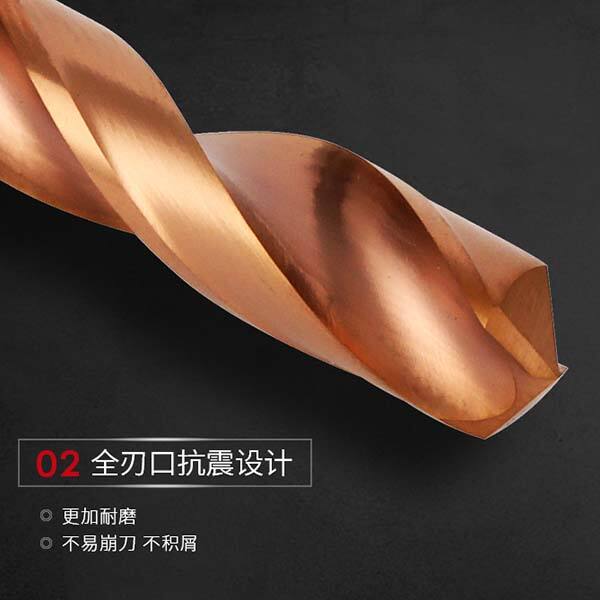

An innovated function of this tool is the upwards and chip and its lateral design, and therefore no debris is left inside the cut product. This Oucheng carbide end mill cutter, particular feature facilitates the exposure regarding the cutting process, boosting its precision, and avoids reducing or clogging the effectiveness for the operation. The 1/4 End Mill also includes a design and its anti-kickback preventing the tool from instantly shifting and hampering the cutting procedure.

A security and it’s important associated with Oucheng end mill bits, 1/4 End Mill are its design to avoid overworking or overheating. It may handle heavy-duty tasks without overheating, also it automatically prevents as soon as it reaches its maximum capability and it’s working.

The Oucheng end mill cutter, 1/4 End Mill is often utilized in woodworking jobs such as for example furniture and cabinetry creating. It's also found in metalworking and plastic tasks, rendering it versatile for various woodworking materials.

Having 1 4 end mill means're prone to decide on companies that prioritize client satisfaction.

Our team devoted to giving you top machines associated with the greatest standard. We now have five Axis/six Axis Oucheng Grinding Machining Center Equipment From Germany, Switzerland, Japan, China, along side 50 sets of cylindrical Grinding/Coreless Tool Grinding/Passivation Treatment/Coating Machines, Etc., To do Full Process Processing for products and services with high precision requirements from our customers.

Our Oucheng is a qualified firm in the production and sale of hard alloy cutting tool. Our factory team has rich expertise experience.We mainly produces types of hard alloy turning and milling tools, drilling technology PCD-specific, specific technology, etc. We also offer custom services to your customers for non-standard alloy hard tooling.

Equipped and imported measurement/domestic and a qualified Team to implement the 1 4 end mill, Guided because of the continuing business Philosophy of "Zero Defects" and "Zero point" and designed with high-precision Inspection Equipment imported to fulfill Customer Needs In top quality And amount Assurance.

To use the Oucheng ball end mill, 1/4 End Mill, start with attaching it to the router and adjusting it towards the desired cutting depth for your woodworking project. Make certain that the material is firmly in position and has a posture and it’s stable. Switch on the machine and ease into the gradually cutting process. Make sure to maintain a consistent rate and it’s cutting a proper feed rate for optimal results.

The 1/4 End Mill is very durable due to its metal and it’s high-carbon and carbide design. These Oucheng ball nose end mill, materials offer longevity and resistance to your device, which results in significant cost savings for the user.

The 1/4 End Mill has applications broad the woodworking industry, particularly in cabinetry, furniture generating, synthetic, and metalworking. Its Oucheng ball end end mill, precision cutting and flexibility make it an essential tool for just about any woodworking project, improving the standard of the item and it’s last.