Carbide End Milling: The Cut Above the Rest

Carbide end milling is an innovative way to shape and form metal into precision parts, similar to the Oucheng's product like 1 2 end mill carbide. This process offers many advantages over traditional methods, including improved efficiency, accuracy, and safety.

Carbide end milling provides a more precise and efficient way to cut metals, the same as carbide center drill built by Oucheng. This process saves time and money by reducing the number of passes needed to complete a task. It also allows for the creation of complex shapes and forms that would be difficult with traditional methods.

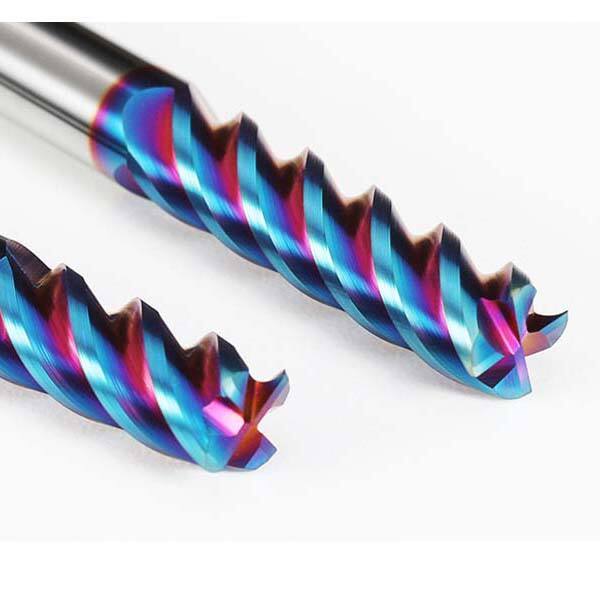

Carbide end milling has seen a lot of innovation in recent years, particularly in the areas of tool design and cutting edge technology, similar to the Oucheng's product like 2 flute end mill for aluminum. The use of diamond-like carbon coatings on cutting tools has improved the quality and performance of these tools.

One of the biggest advantages of carbide end milling is the improved safety it offers, also the 2mm endmill produced by Oucheng. Because the process is faster and more consistent, it reduces the risk of accidents and injuries. Additionally, carbide end mills are built to withstand high temperatures and pressure, making them safer to use in the metalworking industry.

Carbide end milling is an uncomplicated process that requires minimal training, as well as the Oucheng's aluminum roughing end mill. To use this technique, a cutting tool is attached to a milling machine, and the metal is fed into the machine. The machine then moves the cutting tool along the surface of the metal, removing material until the desired shape or form is achieved.

Our Oucheng is a leading enterprise into the design manufacturing, production, and distribution of cutting tools produced from hard alloy. We certainly are a combined group of who have a great deal of knowledge. Our principal products hard alloy milling, turning and drilling equipment. We also provide modified services towards the customers for non-standard tools manufactured from hard alloy.

Equipped and imported measurement/domestic and a qualified Team to implement the carbide end milling, Guided because of the continuing business Philosophy of "Zero Defects" and "Zero point" and designed with high-precision Inspection Equipment imported to fulfill Customer Needs In top quality And amount Assurance.

All of us invested in proclaiming to supply you top quality. We very own six axes/five axis Oucheng grinding centers for machining made in Germany, Switzerland and Japan along with 50 sets of coreless and tooling/passivation/cylindrical grinding, etc. to complete full-process processing products with a top precision demands.

Ultimately, carbide end milling empowers you to demand better service and relish it if it is delivered.