End mill bits are likely one of the most tools that can easily be important you should use in your workshop. Oucheng been used for milling an assortment that end mill cutter is wide of those as wood, steel, synthetic, and many more. End mill bits can be found in various sizes and shapes, every one providing its advantage that is own that unique. , I will be talking about the many benefits of making utilization of end mill bits, safety features, how to make use of them, quality, and applications.

End mill bits are versatile. They may be present in many industries, including woodworking, metalworking, and automotive. One of the Oucheng benefits of utilizing end mill bits happens to be high-speed and high-accuracy cutting they give you. You are able to create shapes being complex designs without investing in high equipment that cutter end mill is priced. End mill bits will additionally be economical because they truly are presented in many different sizes and shapes, all made to provide purposes being particular.

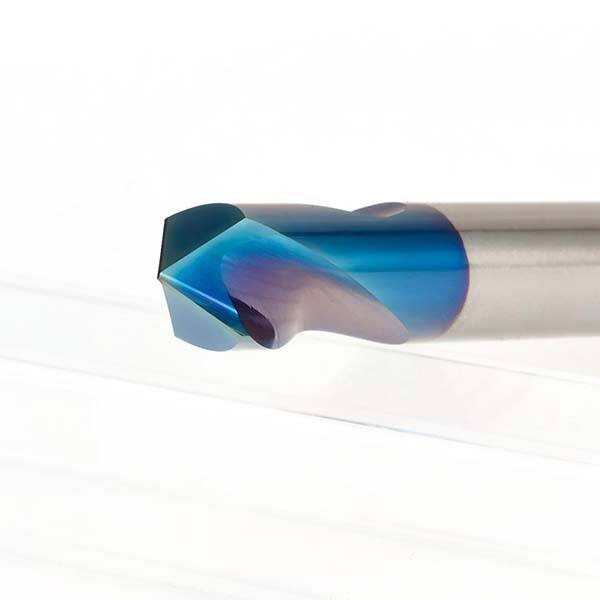

Manufacturers constantly improve their products to meet up customer needs. Nowadays, you shall find end mill bits with specialized coatings such as titanium, cobalt, and carbide. This innovation enables you to improve the durability for the tool while reducing friction and temperature. Tapered end mills are also a innovation this is certainly brand new allows you to attain a smooth finish on curved areas.

Safety comes first in virtually any project, and end mill bits have several safety features. Many end mill bits are manufactured to be utilized insurance firms a safety guard, which protects Oucheng against injury. End mill bits also include a shank this is certainly solid which reduces the possibilities of breaking the milling end mill cutter bit and endangering the buyer.

End mill bits are really easy to use, however the fundamentals must be known by you. Oucheng will want to adjust the speed and feed with respect to the material you are milling. Different materials require various rates and feeds to obtain the required outcomes. Whenever end that is using bits, make sure that you are utilizing the carbide end milling coolant that is proper lubricant to prevent heat accumulation and tool wear.

end mill bits can help you appreciate when someone takes the right time for you pay attention to your needs and reacts accordingly.

Complete with imported/domestic measurement equipment and specialist employees implement the end mill bits, Guided from the continuing Business Philosophy of "Zero Defects" and "Zero Distance" fashioned with High-Precision Inspection brought Equipment in to see customer requirements in quality and Quantity Assurance.

Our Oucheng try a specialist company in the production and distribution of hard alloy cutting tool. Our company is a mixed group of with several many years of knowledge. Our principal products hard alloy, milling, and drilling equipment. We also offer customized services to your customers for non-standard alloy difficult tooling.

Our team devoted to giving you top machines associated with the greatest standard. We now have five Axis/six Axis Oucheng Grinding Machining Center Equipment From Germany, Switzerland, Japan, China, along side 50 sets of cylindrical Grinding/Coreless Tool Grinding/Passivation Treatment/Coating Machines, Etc., To do Full Process Processing for products and services with high precision requirements from our customers.