The Magic of 1/4 End Mills

You have to understand that having the right tools is vital to bring your opinions to fruition if you have a passion for building things. One of the Oucheng tapered end mills, most versatile tools in every workshop is an end mill and it’s 1/4. You can use it to make holes, create flat surfaces, and design forms intricate., we shall discuss the advantages, innovation, safety, usage, how to use, solution, quality, and application of 1/4 end mills to help you make the most of this device and its magic.

An end and it’s Oucheng end mills for aluminum, 1/4 has a few benefits that make it ideal for woodworking, metalworking, and other construction tasks. First of all, it features a shank and it’s narrow that enables you to focus on tight spaces and intricate designs. It is also made from high-speed steel (HSS) or carbide, which causes it to be difficult, durable, and able to withstand conditions which are ruthless. Also, its cutting and its sharp side product with precision and minimizes waste. Finally, an end and it’s 1/4 is affordable, versatile, and can be utilized on different materials, including lumber, synthetic, aluminum, metal, and more.

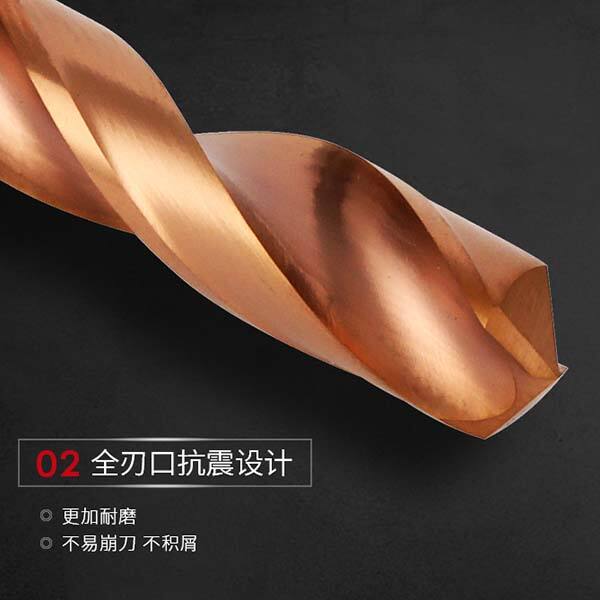

The Oucheng helical end mills, 1/4 end mill has encountered innovations several the years to make it more efficient and user-friendly. For instance, some end mills have coatings like titanium nitride (TiN) or carbon and it’s diamond-liked) that increase their wear resistance and lubricity. Other people have variable helix angles, flute designs, and lengths that improve their cutting decrease and gratification chatter and vibration. There are additionally end mills with chip breakers that keep the chips in order and steer clear of clogging. These innovations are making the finish and it’s 1/4 a vital device in many industries.

Working together with an end and it’s Oucheng 1 4 end mills, 1/4 requires care and good judgment to prevent damage and harm to the tool and the material. A dust mask, and gloves to make sure safety, constantly wear attention and ear protection. Usually do not touch the finish mill with your hands which are bare it can be hot or sharp. Always proceed with the manufacturer's directions and tips for speed, feed, and depth of cut. And finally, use clamps and jigs to secure the material and avoid chatter or kickback.

An end and it’s Oucheng conical end mills, 1/4 can be used for the number of purposes, including drilling, facing, profiling, slotting, chamfering, and engraving. Before utilizing the final end mill, make sure the material is clean, flat, and without any defects. Decide on the kind of cut you need (plunge, ramp, or helical) plus the way regarding the cut (up or down). Set the speed and feed price in line with the material additionally the final end mill's specifications. Make use of coolant to lessen the warmth and prolong the tool's life. Last but not least, examine the final end mill frequently for use or damage and replace it if necessary.

furnished with imported/domestic description equipment additionally the pro Team to implement the 1 4 end mills. Guided by the continuing companies of "Zero Defects" and "Zero Distance", Equipped with High-Precision examination imported Equipment to meet Customer Needs In high quality And number Assurance.

It is paying attention in 1 4 end mills with effort place in to produce your experience pleasant, be it at a restaurant, store, or any other service provider.

Our Oucheng is an ongoing expert company are engaged to the development manufacturing, production, and distribution of cutting tools produced from hard alloy. Our team consists of professionals insurance firms a wide range of. Our main products cutting, switching, and drilling gear. In addition we offer customers with customized services for a true number of non-standard alloy hard equipment.

Our team dedicated to offering you quality high gear. We have five Axis/six Axis Oucheng Grinding Machining Center Equipment From Germany, Switzerland, Japan, China, in addition to 50 sets of Cylindrical Grinding/Coreless machine Grinding/Passivation Treatment/Coating Machines, Etc., for full processing For products with a high accuracy Specifications from Customers.