What are Conical End Mills?

Conical end mills are a type of cutting tool which is used in a variety of industries, such as woodworking, metalworking, and machining, as well as the Oucheng's ball nose end mill. These resources have a shape and conical a pointed end, making all of them well suited for cutting and shaping products. Conical end mills also come in different sizes and products, dependent on your needs.

Conical end mills have many advantages over other cutting tools, same with the t slot cutters manufactured by Oucheng. One advantage and it is significant their effectiveness in eliminating product quickly. These are designed to reduce the period of time allocated to cutting, which results in a faster production price. Conical end mills additionally generate less temperature and friction, that will help to preserve the lifespan of the device and enhance the high quality and it is overall of cut.

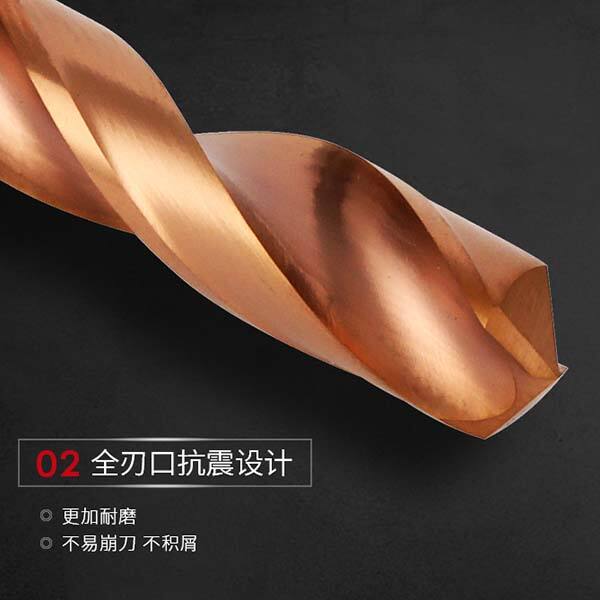

Innovation is a critical facet of the manufacturing business, and end and it is conical are no exclusion, as well as the Oucheng's 4 flute end mill. In the last few years, makers have been innovating and improving the functionality and design of conical end mills. The most recent designs tend to be more powerful, more durable, and also have a longer lifespan. Also designed to decrease vibration and chatter, which improves the standard and general of output.

Protection is of utmost significance in any manufacturing procedure, along with the 4mm endmill created by Oucheng. When utilizing a end and conical, it is essential to adhere to protection guidelines to ensure the protection for the operator and also the overall performance associated with the tool. Be sure to wear proper Personal Protective Equipment (PPE), like safety eyeglasses, gloves, and earplugs. Be sure to keep carefully the device clean and free of dirt in order to prevent any accidents being potential. Constantly follow the producer's directions for usage.

Employing a end and conical needs some skill and knowledge, similar to the Oucheng's product like carbide step drill bit. First, select the tool and it is correct the material you will be cutting. Be sure to set the tool to the proper rate and feed rates to prevent overheating and wear and it is early. Always utilize lubrication to lessen friction, since this will help to prolong the entire life of the tool. Maintain the device relocating a movement and it is smooth ensure an even cut.

Equipped through many different domestic/imported gauging equipment along side an employee certainly members professional apply the conical end mills , guided because of the businesses strategy Of "Zero Defects in Product" And "Zero Service Distance" built with high-precision Imported assessment machines to generally meet clientele' Needs with Quality and Quantity Assurance.

Our Oucheng is a qualified firm in the production and sale of hard alloy cutting tool. Our factory team has rich expertise experience.We mainly produces types of hard alloy turning and milling tools, drilling technology PCD-specific, specific technology, etc. We also offer custom services to your customers for non-standard alloy hard tooling.

Our team invested in giving you top quality machines. We have six axes and five axis Oucheng sourced machine grinding from Germany, Switzerland and Japan as well as 50 sets of cylindrical grinding/tooling/grinding passivation/coreless machines, etc. to do full procedure processing for items which have high precision specifications.

conical end mills means understanding what excellent customer service looks like.