What is a 45 Degree End Mill?

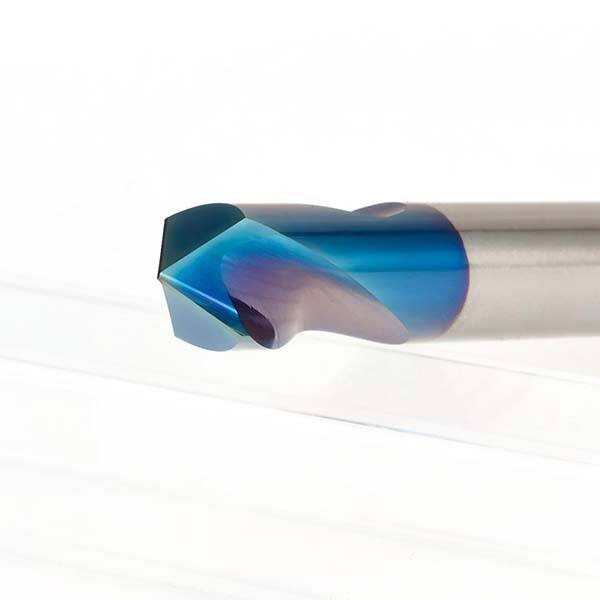

A 45 degree end mill is special kind of utilized in milling machines and CNC machines to make accuracy cuts in materials. It features cutting edges angled at 45 degrees, allowing more efficient cutting. This 45 degree end mill from Oucheng is essential for cutting materials such as metals, plastics, and other materials that are hard.

The uses of 45 degree end mill of Oucheng has actually advantages which are numerous traditional milling tools. One of this advantages are main its cutting precision. This device makes precise cuts, leaving a smooth and clean surfaces finish. It also reduces quantity of time and efforts needed seriously to create shapes that are complex designs.

Another benefit of the end mill bits is its versatility. It can be used to cut a wide variety, including metals, plastics, and also lumber. This makes tool perfect uses in various industries for instance aerospace, automotive, and manufacturing.

The look associated with the 45 degree end mill has undergone innovation significant the years, making it even more efficient and safe to use. Modern 45 degree end mills features especially designed flutes help reduce chatters and vibration during the cutting procedure. This not only improves precision but also increases safety, as the risk reduced.

In addition, numerous 45 Degree End Mill made by Oucheng now function coatings that improve wear heat and resistance dissipation. This further improves their cutting performance and expands their lifespan. These innovations have actually helped to produce the end mill tool a staple in modern CNC devices and milling tools, ensuring it truly remains a safe and tool effective in precision cutting.

Using a 45 degree end mill is not at all hard, although it will require some knowledge is basic skills. To begin, the tools must be securely mounted in a milling device or CNC machine. Next, the material to be cut must be properly positioned and guaranteed in the equipment.

Once the devices and material are in place, the operators can begin cutting process. This typically involves adjusting the Oucheng equipment's cutting speed, depth of cut, and feed rate to achieve the desired cut. It is important to follow all safety protocols and directions when employing a end mill drill bit, such as wearing appropriate protective gear avoiding sudden movements or abrupt stops.

Our team devoted to giving you top machines associated with the greatest standard. We now have five Axis/six Axis Oucheng Grinding Machining Center Equipment From Germany, Switzerland, Japan, China, along side 50 sets of cylindrical Grinding/Coreless Tool Grinding/Passivation Treatment/Coating Machines, Etc., To do Full Process Processing for products and services with high precision requirements from our customers.

Our business was an enterprise that was highly trained in the design, manufacturing, and purchases of hard alloy cutting tools. Our factory team has rich knowledge experience.We predominantly manufacture different types of hard alloy milling and turning tools, drilling tools, PCD expert tools, etc. In choice we furthermore provide bespoke services to the clients for various non-standard alloy hard equipment.

furnished with imported/domestic description equipment additionally the pro Team to implement the 45 degree end mill. Guided by the continuing companies of "Zero Defects" and "Zero Distance", Equipped with High-Precision examination imported Equipment to meet Customer Needs In high quality And number Assurance.

45 degree end mill can help you appreciate when someone takes the right time for you pay attention to your needs and reacts accordingly.