Have you been sick and tired of utilizing the exact same end and it’s old with restricted abilities and gratification? Well, say hello to your innovation and it’s latest in end mill technology – the Oucheng flat end mill, four-flute end mill! This article will give the product innovations, advantages, usage and applications, so better read this.

This device is particularly designed to offer precision and high-speed performance and it’s cutting different materials for example steel, plastic, foam, and lumber. This product has many advantages that you can be benefit. The following are some of its benefits.

1. Higher Efficiency - The Oucheng tapered end mills, four end and its flute cuts faster and smoother as a result of increased number of flutes.

2. Improved Surface Finish - The four end and its flute's cutting sides create a smoother surface finish after each cut, reducing the need for additional finishing.

3. Increased Tool Life - Due to the four end and its flute's increased flute count, there's a reduced load per flute, which improves tool life, reduces device use, and stretches the device lifespan.

4. Versatility - The four end and its flute is ideal for many applications, including contouring, slotting, and pocketing. They are suitable for an assortment and it’s wide of, including alloys, plastics, and more.

Innovation is vital within the manufacturing industry to generate tools that can supply the accuracy and its greatest and performance. It also has an innovation that is done to make sure that this product is truly efficient to end-users. The Oucheng roughing end mill, look of four end and its flute has evolved to meet up with high-performance requirements, such as for instance:

1. Optimized Flute Geometries - The flute geometries of this four-flute end mill are designed to improve chip evacuation, reduce heat buildup, and increase efficiency and it’s cutting.

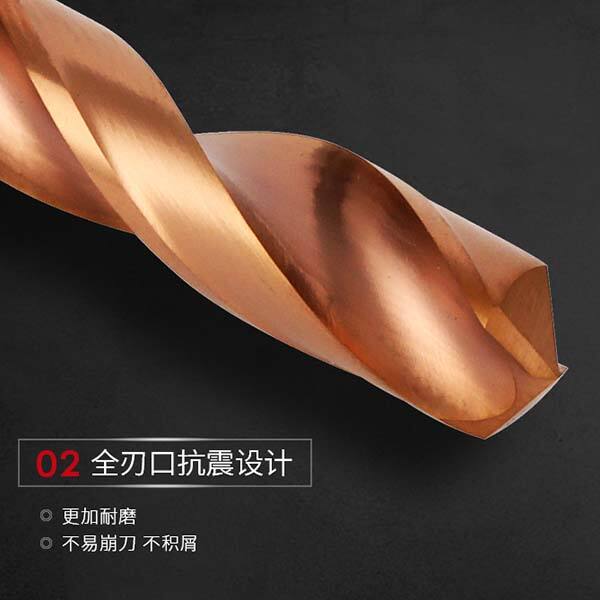

2. greater Helix Angles - The four end and its flute's helix angle is one of the most essential features that enhance its cutting performance. A greater helix angle decreases opposition and it’s cutting minimizes tool vibrations, and offers a smoother cutting experience.

3. Advanced Coatings - Advanced coatings enhance the cutting performance associated with four end and its flute, increasing tool life and reducing deterioration. The coatings also improve chip movement and minimize temperature build-up regarding the edge and it’s cutting.

Safety is a top priority while using the Oucheng helical end mills, four-end mill and it’s flute. We always prioritize you safety, so better follow the guidelines we put on the item. Listed below are a security and it’s few you should look at before using the tool:

1. Always wear individual equipment and it’s protective such as for example security cups, earplugs, and a face shield.

2. Ensure that the four end and its flute is securely fastened to the spindle before use.

3. Verify the tool and it’s cutting rate and feed parameters to complement the product requirements.

4. Keep the location and it’s cutting from obstructions and potato chips.

5. Keep both hands and fingers far from the finish mill and it’s rotating.

Using the Oucheng end mill tool, four end and its flute is straightforward. This product is user-friendly making it easier to use. Here is a guide to aid the tool is employed by you effectively:

1. Securely fasten the four end and it’s flute regarding the spindle and adjust the speed and feed parameters based on the material's requirements.

2. Position the workpiece and securely ensure it is clamped on the worktable.

3. Lower the four end and its flute on the workpiece, ensuring that the cutting edge doesn't touch the product.

4. Turn on the spindle while making a light initial cut to determine the trail and it’s cutting.

5. Begin the cutting process, but make sure to help keep the material free from potato chips and obstructions.

Our team are dedicated to providing machines of finest quality. We own six axes/five axis Oucheng grinding centers for sourced machining from Germany, Switzerland and Japan along with 50 sets of cylindrical grinding equipment/coreless grinding/passivation treatment/coating equipments, etc. to accomplish full-process processing for products utilizing the accuracy highest specifications.

Loaded with Imported/Domestic gauging machines And Professional Personnel To make use of the four flute end mill , guided by the Business Philosophy of "Zero Defects in item" plus "Zero Service length" designed utilizing the highest-precision Inspection Equipment to fulfill Consumer wants With Quality And quantities confidence.

Our Oucheng try a specialist company in the production and distribution of hard alloy cutting tool. Our company is a mixed group of with several many years of knowledge. Our principal products hard alloy, milling, and drilling equipment. We also offer customized services to your customers for non-standard alloy difficult tooling.

It really is like having a four flute end mill businesses or those who truly care in connection with satisfaction.