The Amazing 1/4 Inch End Mill - A Must-Have Tool in Every Workshop

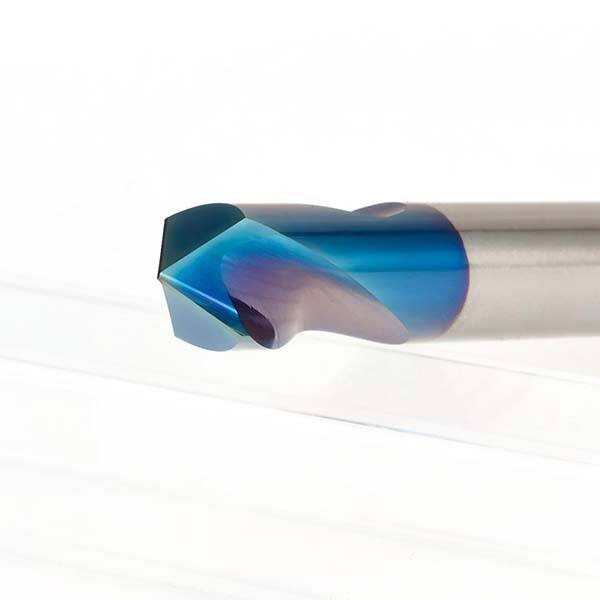

The 1/4 Inch End Mill can be an amazing device every workshop needs to have just like having Oucheng carbide end mill cutter. This might be a cutting tool used for removing material through the workpiece. It features a cylindrical shape with sharp teeth located on the end and across the advantage. Allow me to share five explanations why this device should be had by you in your toolbox.

The Oucheng 1/4 Inch End Mill is a versatile tool can cut through an array of materials. Along with its capacity to quickly eliminate product and effortlessly, it saves effort and time. Additionally it is economical, since it persists more than many other cutting tools. Additionally, the tool's design enables accuracy and accuracy, required for many applications.

The 1/4 Inch End Mill and the Oucheng tapered end mills has proceeded to evolve with advancements in technology. Today, you'll find end mills produced from many different materials, including high-speed metal cobalt, and carbide. These materials have actually properties that are superior allow for greater efficiency, accuracy and rate when slicing through material. Revolutionary design features, such as adjustable helix flute and angle spacing, also donate to the tool's exemplary performance.

The use of cutting tools poses risks, so it will be required to follow safety recommendations with all the Oucheng 1/4 Inch End Mill. Always be certain to wear safety glasses, work gloves and give a wide berth to loose clothes can catch from the tool. Also, keep consistently the workpiece secured and straight avoid standing right in front from it once the end mill is in motion.

To use a 1/4 Inch End Mill or even Oucheng flat end mill, you'll want to connect it to a milling machine. The device will help you go the workpiece whilst the last end with accuracy. Set the cutting depth, speed, and feed rate, making certain your tool is operating at optimal efficiency. Then, allow the device do the work. Keep in mind this cutting rate adjust as needed. Always proceed with the maker's instructions to discover the best results.

Our firm is a professional Oucheng into the production and sale of a difficult alloy cutting machine. All of us comprises of experts who possess a great deal of expertise. Our principal products difficult alloy turning, milling, and drilling equipment. As well we also offer customers with customized services to work with a variety non-standard alloy hard equipment.

Our team invested in giving you top quality machines. We have six axes and five axis Oucheng sourced machine grinding from Germany, Switzerland and Japan as well as 50 sets of cylindrical grinding/tooling/grinding passivation/coreless machines, etc. to do full procedure processing for items which have high precision specifications.

You notice the tiny affairs that produce a 1 4 inch end mill , like an amiable smile or a helpful attitude when you have close service awareness.

Equipped through many different domestic/imported gauging equipment along side an employee certainly members professional apply the 1 4 inch end mill , guided because of the businesses strategy Of "Zero Defects in Product" And "Zero Service Distance" built with high-precision Imported assessment machines to generally meet clientele' Needs with Quality and Quantity Assurance.