Are you fed up with suffering dull drill bits that break easily or are unable to drill through tough materials? Then maybe it's time to pay attention to updating to tungsten carbide metal drill bits. Oucheng tungsten carbide metal drill bits this innovative kind of drill bit provides several advantages over conventional people, which makes it the option that is perfect whoever desires to work faster, more proficiently, and much more safely.

Options that come with Tungsten Carbide Metal Drill Bits One of the main advantages of tungsten carbide metal drill bits could be the exemplary durability. Oucheng tungsten carbide drill bits made of a mixture of tungsten carbide and cobalt, these bits have the ability to withstand high-temperature and conditions being high-pressure which makes them perfect for drilling through hard and materials that are thick as steel, concrete, stone, and timber. In fact, tungsten carbide metal drill bits are as much as 10 times more durable than traditional metal bits, which means you will not need certainly to replace them as often and that can cut costs in the run that is very long.

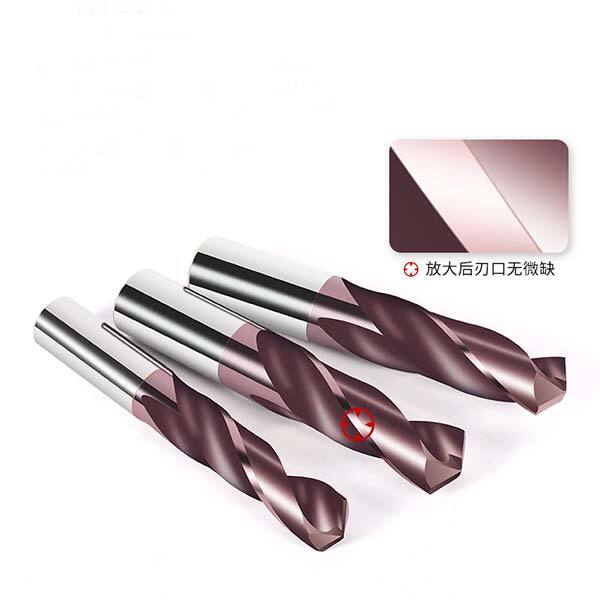

Another advantage of tungsten carbide metal drill bits may be the precision.

These bits have actually fine, sharp sides that permit them generate accurate and clean holes with reduced work. Due to this, you'll achieve professional-level outcomes even if you should be not a DIYer seasoned.

Tungsten carbide metal drill bits also function some security that is innovative that are not present in traditional drill bits. Oucheng carbide end milling By way of example, some carbide this is certainly tungsten drill bits have a hex shank design that stops them from wobbling or sliding within the chuck, which may cause accidents or injury to your workpiece. In addition, some carbide that is tungsten drill bits have an unique flute design that helps remove poker chips and debris through the opening whilst you drill, reducing the risk of clogging or overheating. This particular feature additionally improves the bit's temperature dissipation and reduces the possibility of breaking or breaking.

Utilizing carbide tungsten drill bits is simple, and requirements no special abilities or knowledge.

Simply select the size that's right number of bits for the work, insert it to your drill's chuck, and securely tighten it. Then, adjust your drill's torque and speed settings based on the product you may be drilling therefore the size associated with gap you ought to produce. Oucheng carbide end mill cutter to ensure probably the most useful results, it is important to keep a steady and drilling straight and to make use of a lubricant or coolant to avoid overheating and extend the life span of your bit. Additionally, it is recommended to sporadically always check your bit's sharpness and replace it when it becomes dull or damaged.

Tungsten Carbide Tools (TCT), our company is dedicated to providing our customers along with the quality that is greatest tungsten carbide metal drill bits and outstanding solution. Oucheng end mill bits our items are made of premium-grade materials consequently they are usually afflicted by quality procedures that are rigorous be sure their dependability, durability, and gratification. We additionally offer a range this is certainly wide of and forms of tungsten carbide metal drill bits to fulfill certain requirements and preferences of our customers. We now have the tool that is right your task whether you could be a specialist or maybe a DIY enthusiast.

Our Oucheng is a reputable firm produces and distribution of hard alloy cutting technology. Our team of factory employees has expertise and experience.We mostly produce several kinds of hard alloy milling and turning tools, drill apparatus, PCD-specific tools. We additionally provide customized services to your customers searching for non-standard hard alloy.

Our team is invested in giving you with higher machines of the product highest quality. We've got six axes and five axis Oucheng grinding machine in Germany, Switzerland and Japan aswell as 50 sets of cylindrical grinding/coreless tools, grinding/passivation treatment/coating equipments, etc. to deliver full procedure for products with a top precision specifications.

Equipped through many different domestic/imported gauging equipment along side an employee certainly members professional apply the tungsten carbide metal drill bits , guided because of the businesses strategy Of "Zero Defects in Product" And "Zero Service Distance" built with high-precision Imported assessment machines to generally meet clientele' Needs with Quality and Quantity Assurance.

tungsten carbide metal drill bits means understanding what excellent customer service looks like.