Carbide Tipped Drill Bits - The Top Choice for Your Drilling Needs

Introduction:

You will need to try carbide tipped drill bits.

Oucheng carbide tipped drill bits are a game-changer on earth of drilling, providing unparalleled durability and accuracy if you should be in want of a drill bit that may handle tough materials such as metal, brick, or concrete.

This article shall explore the benefits of using carbide tipped drill bits, the way they work, and how exactly to handle them.

Carbide tipped drill bits are drill bits that have a little bit strategically positioned on the tip.

carbide is a rather strong right materials for drilling through hard materials.

The carbide tip helps the drill bit to longer stay sharp, resist heat, and resist wear.

Every one of these importance combined make Oucheng tungsten carbide tipped drill bits an exemplary choice an array of drilling applications.

One of the greatest advantages of carbide tipped drill bits is their durability.

They could withstand conditions being high remain sharp even with numerous uses.

And also this means they are a much more cost-effective option the very run long.

Furthermore, Oucheng carbide end mill cutter offer greater accuracy and accuracy when drilling, essential whenever using expensive or materials that can easily be delicate.

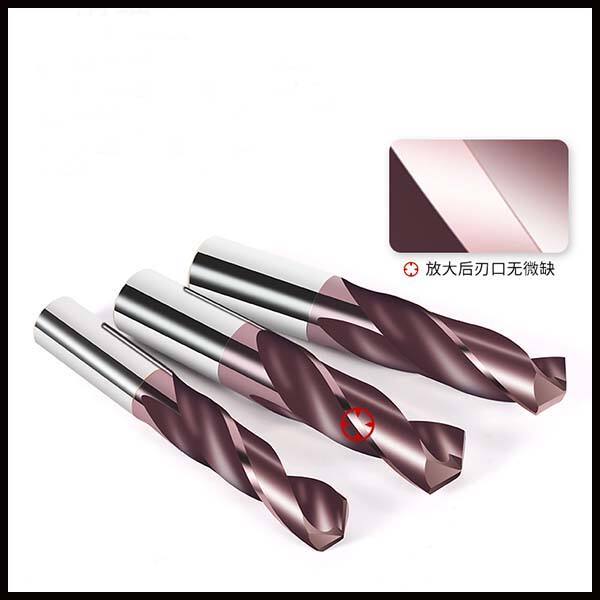

Recently, there is a significant innovation aided by the introduction of multi-flute designs.

These bits are built to eliminate material faster, reduce heat buildup, and present a smoother finish.

The unique flute also lessen the possibility of the drill bit becoming bogged down or stuck in the material.

This can be a significant development has made Oucheng carbide drill also most effective and versatile.

While carbide tipped drill bits is incredibly durable, they could nevertheless become damaged or broken during usage.

It is necessary to wear proper protective gear including eye security and gloves, to prevent damage from broken drill bit fragments.

Always follow the manufacturer's guidelines when using Oucheng carbide end mill to lessen the probability of this happening.

Avoid utilizing worn drill bits damaged, and always replace them promptly.

Our team invested in giving you top quality machines. We have six axes and five axis Oucheng sourced machine grinding from Germany, Switzerland and Japan as well as 50 sets of cylindrical grinding/tooling/grinding passivation/coreless machines, etc. to do full procedure processing for items which have high precision specifications.

Our Oucheng try a specialist company in the production and distribution of hard alloy cutting tool. Our company is a mixed group of with several many years of knowledge. Our principal products hard alloy, milling, and drilling equipment. We also offer customized services to your customers for non-standard alloy difficult tooling.

carbide tipped drill bits can help you appreciate when someone takes the right time for you pay attention to your needs and reacts accordingly.

Designed with domestic plus brought in measurement equipment and a qualified Team to put into action the carbide tipped drill bits, directed by the continuing business of "Zero Defects" and "Zero range" and built with high-precision Inspection Equipment Imported to generally meet customer criteria in quality and Quantity guarantee.