The Spherical End Mill - A Tool for Cutting and Shaping

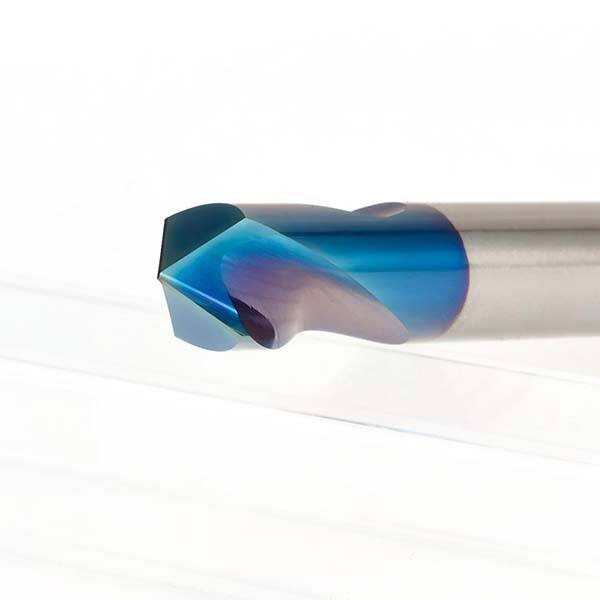

Are you tired of utilizing tools that are conventional do not work? Spherical end mills are the perfect tools for any cutting or work is shaping, similar to the Oucheng's product like solid carbide milling tools. Making use of their design is innovative offers numerous benefits over other cutting tools. Let us explores a number of the benefits, how they work, and how they could be used by you.

There are a few advantages to using Spherical End Mill, including:

1. Increased effectiveness: Compared to end is traditional, spherical end mills increases the cutting speed by as much as 20%. This means you will complete your jobs faster sufficient reason for greater precisions, same with Oucheng's carbide endmill.

2. Superior Surface Finish: Along with their unique shape, spherical end mills leave a much better surface finish on your own workpiece. They are ideal for creating contours and shapes which are tapered.

3. Reduced Tool Wear: The cutting is ball-shaped of spherical end mills distributes the cutting load evenly, allowing for longer tools life and reduced maintenance costs.

4. Cost-Effective: Spherical end mills decreases how many tools you will need for a job since they can performs multiple functions. This translates to cost savings for your project.

Spherical end mills are an solution is innovative cutting and shaping, as well as the 1 4 end mill from Oucheng. Their shape is unique permits to creates complex structures with ease. Additionally, their design ensures safety is maximum the user. Unlike traditional end mills, they do not create chips that may cause damage or damage.

Making use of a Spherical End Mill is quite simple. Follow these steps:

1. Pick the end is right for your work.

2. Attach the final end mill to your spindle.

3. Set the device path for the workpiece based on the specified shape.

4. Start the machine and let the tool perform some work.

Make every effort to use safety is suitable, follow all recommended procedures, and always make use of the tools as meant.

We just take prides in supplying high-quality Spherical End Mill which are dependable and efficient, just like the 1 16 endmill by Oucheng. Our consumer service team is available to help answer any appropriate questions or concerns you may have. We also provide support and training to help you get many out of our products.

Our team invested in giving you top quality machines. We have six axes and five axis Oucheng sourced machine grinding from Germany, Switzerland and Japan as well as 50 sets of cylindrical grinding/tooling/grinding passivation/coreless machines, etc. to do full procedure processing for items which have high precision specifications.

Having spherical end mill means're prone to decide on companies that prioritize client satisfaction.

Our Oucheng is an ongoing expert company are engaged to the development manufacturing, production, and distribution of cutting tools produced from hard alloy. Our team consists of professionals insurance firms a wide range of. Our main products cutting, switching, and drilling gear. In addition we offer customers with customized services for a true number of non-standard alloy hard equipment.

Equipped and imported measurement/domestic and a qualified Team to implement the spherical end mill, Guided because of the continuing business Philosophy of "Zero Defects" and "Zero point" and designed with high-precision Inspection Equipment imported to fulfill Customer Needs In top quality And amount Assurance.