CNC End Mills for Wood – Your Ultimate Woodworking Buddy.

Are you tired of using hand resources to profile and carve wood? Do you want to make your woodworking knowledge more precise and effective? Then end and CNC for timber tend to be your option ultimate if. Oucheng end mill solid carbide to be specifically made resources which may be attach and it’s cutting a CNC device and will efficiently carve, and contour timber focused on your desired design. We shall explore advantages of CNC end mills for timber, their specific development, safety measures, making usage of them, their quality and toughness large and programs that will be often different will gain from their site.

CNC end mills tend to be cutting digitally controlled which will create high-precision cuts on wood with convenience. They are faster, better, and precise than old-fashioned woodworking tools. Here are some advantages of Oucheng carbide drill bits for metal:

1. Huge precision: CNC end mills create precise cuts with great precision, providing a smooth and full clearly perfect.

2. Customization: With CNC end mills, you can develop kinds of personalized lumber with simpleness. You can easily create a range and wide of types and habits on lumber, that will be hard to attain with hand-held resources.

3. Efficiency: CNC end mills reduce steadily the labor needed for carving wood by automating the technique. This saves some right time leads to increased standard of manufacturing in the duration brief.

4. Repetition: CNC end mills can duplicate the same precise design or design the maximum number of times while you would like with similar degree of dependability every time solitary.

5. Increased manufacturing ability: CNC end mills can work on many things of timber simultaneously, enabling the manufacturing of even more things in a very reduced time.

CNC end mills for lumber have withstood development and its tremendous is technical years several. Utilizing the innovation and its latest in the production process, cutting-edge technology was integrated into Oucheng 1 4 end mill, making all of them more efficient and effective in carrying out their tasks specific. Several of those innovations are:

1. Multi-Flute Design: CNC end mills are now created using more flutes regarding the cutting edge, giving them better accuracy, stability, and paid off opposition this might be cutting.

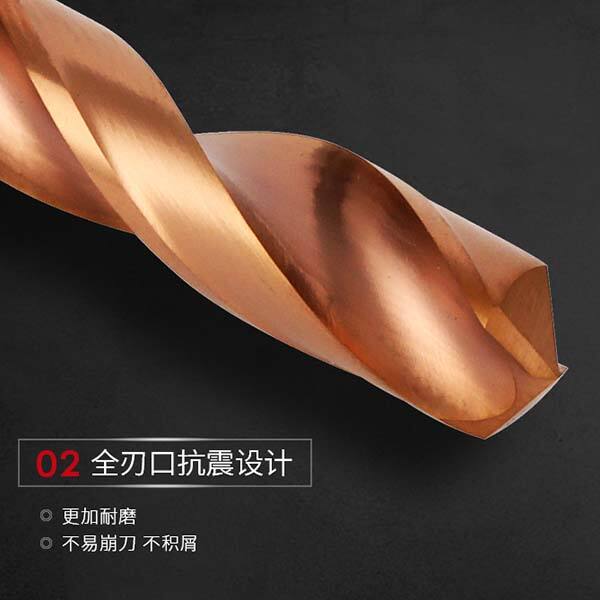

2. Coating Technologies: CNC end mills have high level finish technologies that shield the sources from damage, resulting within a longer device entire life and a sharper cutting advantage.

3. Improved Material: Use of high level product in manufacturing CNC end mills contributes to sharper edges, higher usage weight, and item life prolonged.

Cover comes first regarding using CNC end mills for lumber. Listed here are a protection and its few to bear in mind whenever using end and CNC:

1. Read the manual and it remain individual glued to the protection tips written by producer.

2. Wear protection goggles, gloves, and ear protection while running the equipment.

3. Never ever attain within the product though it is running.

4. Keep consistently the positioning surrounding the Oucheng four flute end mill neat and clear of soil.

To utilize end and its CNC for lumber, some measures must be followed by you standard:

1. Create a design pc software and its utilizing alongside your Oucheng straight flute drill bit.

2. Set the machine up and load the item that's right the apparatus.

3. Set the depth and speed of the unit within the desired amount.

4. Begin the equipment and enable it doing its work.

Our team are dedicated to providing machines of finest quality. We own six axes/five axis Oucheng grinding centers for sourced machining from Germany, Switzerland and Japan along with 50 sets of cylindrical grinding equipment/coreless grinding/passivation treatment/coating equipments, etc. to accomplish full-process processing for products utilizing the accuracy highest specifications.

Our firm was a Oucheng within the production and buy of difficult alloy cutting tool. Our factory team has rich knowledge experience predominantly manufacture different varieties of difficult alloy milling and turning instruments, drilling hardware PCD-specific, specialized tools, etc. Additionally we furthermore offer customers with custom-made services for a range of difficult alloy equipment.

Complete with imported/domestic measurement equipment and specialist employees implement the cnc end mills for wood, Guided from the continuing Business Philosophy of "Zero Defects" and "Zero Distance" fashioned with High-Precision Inspection brought Equipment in to see customer requirements in quality and Quantity Assurance.

When you have good service awareness, you are most likely to acknowledge and thank those who provide cnc end mills for wood .